Printing a Shock

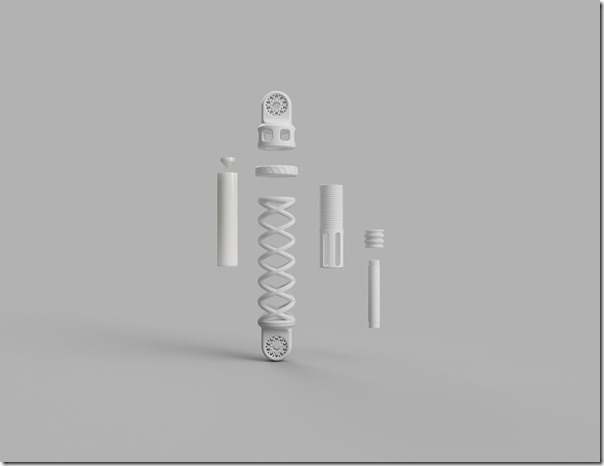

Although this shock absorber is just a demonstration device, its fabrication is rather clever as the materials company that made it, Covestro, used three different materials and three different 3D fabrication processes to make it: First, there’s the outer spring of the 40 x 7-cm part.

Although this shock absorber is just a demonstration device, its fabrication is rather clever as the materials company that made it, Covestro, used three different materials and three different 3D fabrication processes to make it:

First, there’s the outer spring of the 40 x 7-cm part. It was produced with powered thermoplastic polyurethane via the selective laser sintering process.

Then there’s the adjusting screw that, when the shock is assembled, is on the interior of the assembly. In order to perform well it needs to have both strength and hardness. Consequently, it is produced with a polycarbonate. The fused filament fabrication process was used.

Finally, there is the air chamber. It, too, is in the interior of the shock absorber. It was made with a liquid polyurethane resin with a digital light processing method.

According to Lukas Breuers, a marketing manager for 2D and 3D printing at Covestro, “This complex structure would not have been possible with conventional production processes.”

RELATED CONTENT

-

Speed Metal

The grail of metal additive manufacturing is the ability to keep pace with full automotive production. The quest continues.

-

Building Bikes

According to the folks at Sculpteo, a 3d printing and engineering services company based outside of Paris, they built what they describe as “the first ever fully functional bike created using digital manufacturing.” To prove that this is a real bike, not a booth exhibit, the two designers of the bike, Alexandre d’Orsetti and Piotr Widelka, rode it from Las Vegas, where it had been on display at CES, to San Francisco, where Sculpteo has a facility.

-

Printing Prototypes

Skorpion Engineering, an Italian firm with operations in both Milan and Turin, is deploying 3D printers from Stratasys to produce complex prototypes 50 percent faster than it was able to do when it was using clay modeling to produce components.

.jpg;width=70;height=70;mode=crop)